A lot of homeowners are staring at shelves full of “old” tools and wondering if they still matter when every ad is pushing cordless, smart, and connected gear. That feeling isn’t unique—this week, conversations about outdated tech spiked again as sites highlighted “obsolete things” and how fast the world has moved on. The same thing is quietly happening in your toolbox: corded drills, hand saws, old levels, and wired shop lights are being written off as relics, even though many of them can still do serious work with a small upgrade.

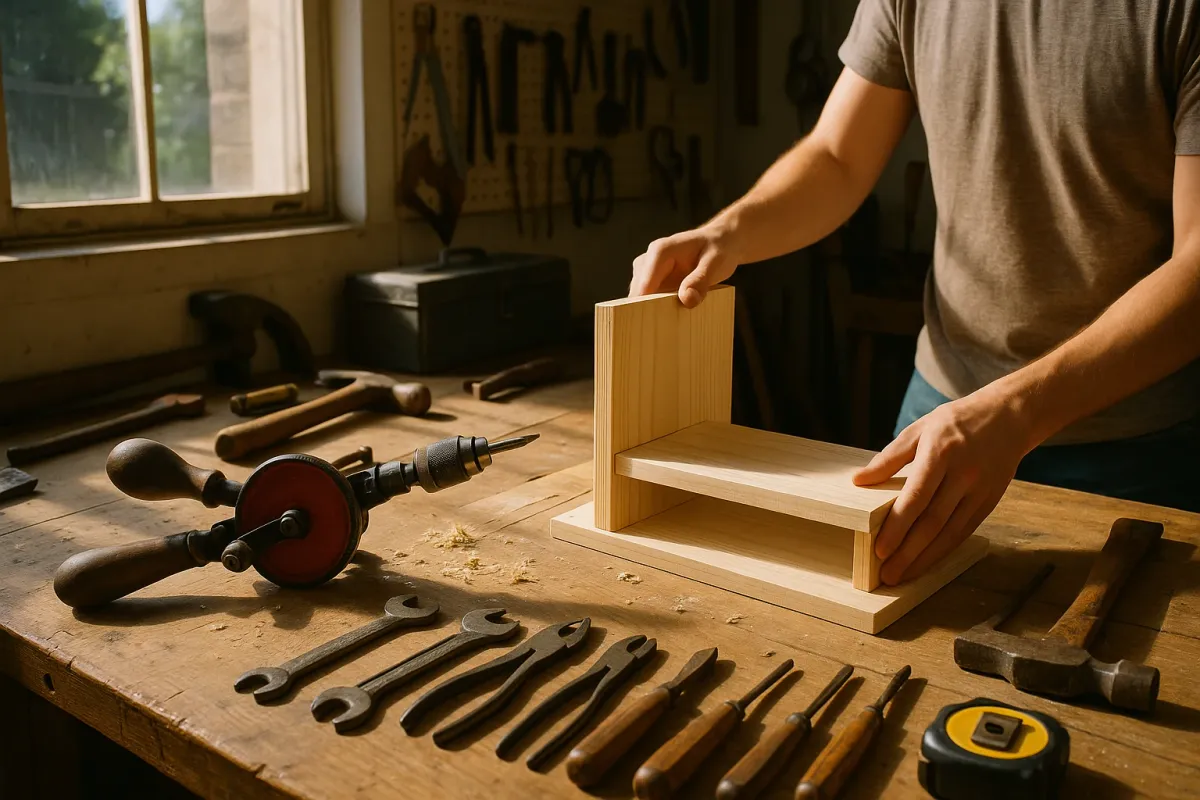

Instead of tossing everything and rushing to buy the latest lithium-powered gadget, you can do what many pros actually do: keep the solid old tools that still work, modernize them where it matters, and fill in true gaps with well-chosen new gear. Below is a step‑by‑step way to audit what you have, fix what’s worth saving, and upgrade only where it genuinely improves safety, speed, or results.

---

Step 1: Audit Your Existing Tools Like A Pro, Not A Collector

Before you buy anything new, lay everything out—hand tools, power tools, extension cords, ladders, even old “junk drawer” items like stud finders and tape measures.

- **Sort by job, not by age.** Group tools into rough categories: cutting (saws, knives, snips), fastening (screwdrivers, drills, nailers), measuring (tapes, levels, squares, stud finders), and support gear (clamps, ladders, lights). This shows overlaps and true gaps.

- **Check the basics: safety and function.** For each tool, ask:

- Does it power on or move freely?

- Any cracks in handles, housings, or cords?

- Is there wobble in moving parts (chucks, blades, wheels)?

- Does it smell like burning or feel hot quickly? (Big red flag for motors.)

- **Be honest about how you actually work.** If you never use your corded jigsaw because swapping blades is a nightmare, that’s a “FIX/UPGRADE” candidate, not dead weight. Sometimes a $10 upgrade makes an “obsolete” tool your go‑to.

- **Note what’s missing.** As you think about common home jobs (hanging cabinets, fixing trim, building shelves), write down tools that would make those tasks safer or faster. This list will matter when you decide what to upgrade later.

**Mark tools in three categories:**

- **KEEP** – Safe, functional, used at least once in the last two years. - **FIX/UPGRADE** – Solid base tool with a clear issue (dull blade, cracked cord, missing accessory). - **RETIRE/RECYCLE** – Unsafe, poor quality, or completely redundant (three identical cheap levels, for example).

This audit step feels boring, but it’s your roadmap. It stops you from buying the fifth screwdriver set when what you really needed was one solid clamp and a good work light.

---

Step 2: Make “Obsolete” Corded Tools Safe And Job‑Ready

Cordless gear is everywhere right now, but many pros still keep corded tools for long, heavy‑duty jobs. If you have old corded drills, circular saws, or sanders, you might not need to replace them—you might just need to make them safe and more pleasant to use.

- **Inspect and repair cords first.**

- Look for nicks, exposed copper, stiff or brittle sections, and loose plugs.

- Minor outer‑jacket damage can sometimes be safely repaired with high‑quality heat‑shrink tubing and electrical tape, but **any exposed conductor, soft spots near the plug, or cracked plug housings are a “replace cord or retire tool” situation**.

- If you’re not comfortable opening the tool to replace a cord, get a repair shop quote; compare that cost to a new tool.

- **Add modern surge and shock protection.**

- Use a **good quality surge‑protected power strip** or **GFCI extension cord** when working in garages, basements, or outdoors. It’s a cheap safety layer for older tools that weren’t built with modern electronics in mind.

- Label one heavy‑duty, GFCI‑protected cord as your “power tools only” cord so it’s always where you need it.

- **Improve handling with new accessories.**

- For corded drills, swap out old, worn chucks if they slip; a fresh keyed or keyless chuck can make an old drill feel new.

- Add **rubber grip sleeves or tape** to metal or slick plastic handles for better control and less fatigue.

- On corded sanders, replace the dust bag with a **shop‑vac adapter** if possible; this dramatically cuts dust and makes the tool feel less dated.

- **Upgrade blades and bits, not the whole tool.**

- A “slow, weak” circular saw is often just running a dull or wrong‑type blade. A modern carbide blade sized correctly can instantly improve cut quality.

- Old drill bits are a major performance killer. A fresh set of high‑speed steel (HSS) bits for wood/metal and masonry bits for concrete can change how you feel about that corded drill.

- **Store thoughtfully so they actually get used.**

- Mount a simple plywood “power tool parking” station on the wall near your outlets. Hang or shelf the corded tools you use most, with their cords neatly wrapped and their key accessories (bits, blades) in a labeled bin directly below.

With a few safety and performance tweaks, a “dinosaur” corded drill can be the tool you reach for when your latest lithium battery dies halfway through a project.

---

Step 3: Sharpen, Clean, And Rescue Hand Tools Before You Replace Them

Headlines about “obsolete” objects remind us how easily good gear gets tossed just because it looks old. Hand tools are especially guilty victims here: rusted, dull, or sticky tools get ignored when they could be fixed in under an hour.

- **Deal with rust safely.**

- Light surface rust on wrenches, pliers, or chisels: scrub with a wire brush or Scotch‑Brite pad and a bit of light oil (like 3‑in‑1 or WD‑40 Specialist).

- Heavier rust: soak overnight in a rust‑dissolver solution or white vinegar, then scrub. Dry thoroughly and coat with a thin film of oil.

- **Sharpen cutting tools properly.**

- **Utility knives:** replace blades; they’re designed to be disposable. Don’t waste time sharpening.

- **Chisels and plane irons:** use a sharpening stone or diamond plate. Flatten the back, then bevel; even a basic “good enough” edge is a massive improvement over dull steel.

- **Hand saws:** many modern cheap saws aren’t worth sharpening, but older, quality saws are. If you’re not ready to learn saw‑sharpening, at least clean the plate and wax it so it cuts smoother.

- **Lubricate moving joints.**

- Apply a drop of oil to pivot points on pliers, tin snips, and adjustable wrenches. Work them back and forth until movement feels smooth.

- Wipe away excess oil so it doesn’t attract dust and debris.

- **Replace worn grips and handles.**

- Wooden hammer or axe handles with cracks near the head are safety hazards; either re‑handle them or retire them.

- You can wrap worn grips on screwdrivers or pliers with self‑fusing silicone tape or heat‑shrink tubing to make them more comfortable and safer.

- **Create a “reach first” hand‑tool kit.**

- Pick the 10–15 hand tools you use constantly (e.g., 16‑oz hammer, #2 Phillips, slotted screwdriver, adjustable wrench, needle‑nose pliers, tape measure, utility knife).

- Put them in a small, dedicated toolbox or tote that lives where you actually work most (not buried in the garage).

You’ll be surprised how many “junk” tools become daily drivers again once they’re sharp, clean, and easy to grab.

---

Step 4: Add Smart, Not Flashy, Upgrades To Fill Real Gaps

Once you’ve rescued the tools you already own, it’s time to bring in a few modern upgrades where they genuinely improve safety, precision, or efficiency. Ignore the hype and focus on tools that solve specific problems you’ve noticed.

- **Target lighting, stability, and dust first.**

- A bright, adjustable **LED work light** with a magnetic base or tripod is more impactful than a flashy specialty tool. Being able to actually see what you’re cutting or fastening instantly upgrades all your existing gear.

- A couple of **solid clamps** (F‑style or quick‑release) turn any table into a makeshift workbench and keep your hands away from blades and bits.

- A compact **shop‑vac or dust extractor** helps older tools (especially sanders and saws) feel more modern by controlling dust.

- **Upgrade measuring and layout tools.**

- A **decent 25‑ft tape measure**, a reliable **bubble level**, and a small **combination square** will do more for your projects than yet another fancy screw bit set.

- If you hang a lot of shelves, cabinets, or gallery walls, consider a **cross‑line laser level**. Prices have dropped, and pairing one with your old hand tools gives you “2025 precision” without replacing everything else.

- **Choose one battery platform (if you go cordless).**

- If you decide to add cordless tools, pick **one major brand** and stick to that battery system. Scattering across different brands drains your budget and shelf space.

- Start with the tools you’ll use most: usually a **drill/driver** and an **impact driver**. Your sturdier old corded tools can stay for heavy, continuous work.

- **Look for compatibility with old tools.**

- Some modern accessories are backward‑compatible with older gear: sanding discs, saw blades, drill bits, and even dust‑collection adapters.

- When buying new, favor standard sizes (e.g., 6‑1/2" or 7‑1/4" saw blades, common shank sizes on drill bits) so the same consumables work across both old and new tools.

- **Invest in safety gear as “tools,” not afterthoughts.**

- Eye protection, hearing protection, and a good respirator or dust mask shouldn’t feel like optional extras. They are part of your tool setup.

- Keeping this gear within reach—hung on a hook above your main work area—means you’ll actually use it, which makes every other tool upgrade worth it.

This step is where brand‑new tech and “obsolete” hardware meet. The goal isn’t to chase gadgets—it’s to let a few smart modern pieces lift the whole setup.

---

Step 5: Organize For Fast Setup So Projects Actually Get Finished

The real difference between a pro‑looking workspace and a frustrating hobby setup isn’t just the price of tools—it’s how fast you can get from “idea” to “tools out and working.” This is where many older tools get abandoned: if they’re buried, tangled, or missing parts, you’ll reach for whatever cheap new thing is closest.

- **Create clear “zones” for tasks.**

- Example zones: **cutting**, **drilling/fastening**, **finishing/sanding**, and **measuring/layout**.

- Store tools in or near their zone. Your circular saw, miter saw, and jigsaw go in “cutting,” your drills and drivers in “drilling/fastening,” etc.

- **Package each tool with its essentials.**

- Drill lives with its bits and drivers.

- Circular saw lives with extra blades, clamp, and safety glasses.

- Sander lives with sandpaper sheets/discs and a dust mask.

- Use small, labeled bins or pouches so you’re never hunting for the “one missing piece” that stops a job.

- **Use vertical storage for awkward tools.**

- Pegboard, French cleats, or simple screw‑in hooks can get hoses, cords, levels, and long clamps off the floor and into view.

- Old tools that you can see and reach are much more likely to get used, even if they aren’t the latest model.

- **Set up a “5‑minute workbench.”**

- A foldable workbench or a sheet of plywood you can drop onto sawhorses can live against a wall when not in use.

- Keep the sawhorses and clamps next to it. Being able to go from “everything away” to “ready to cut” in under five minutes is what turns ideas into finished fixes.

- **End each project with a quick reset.**

- Blow off or vacuum tools, wrap cords, return bits and blades to their bins, and hang everything back in its zone.

- Take 5 extra minutes to put a small note on tools that need attention (“jigsaw blade adapter broken,” “need new sanding discs”). Next time you’re near a hardware store or browsing online deals, you know exactly what to look for.

When your setup is simple to deploy and simple to reset, those “obsolete” tools stop gathering dust and start putting in work again.

---

Conclusion

The fast pace of new tech makes it feel like anything older than a few years—phones, cameras, and yes, tools—belongs in the trash. But as people keep rediscovering in stories about “obsolete” objects, older gear often has plenty of life left if you treat it right. In your home workshop, that means auditing what you own, making corded tools safe and usable, sharpening and cleaning hand tools, choosing a few strategic modern upgrades, and organizing everything so it’s ready in minutes.

You don’t need a brand‑new, influencer‑approved shop to do solid work. You need tools—old and new—that are sharp, safe, and easy to grab. Start with what you have, improve what you can, and only then buy what you’re truly missing. That’s how you turn “obsolete” into “ready to fix anything.”

Key Takeaway

The most important thing to remember from this article is that following these steps can lead to great results.